Computational Fluid Dynamics, or CFD modeling, is a powerful virtual tool used by engineers and scientists to simulate fluid flow, heat transfer, and related phenomena. If you’ve ever wondered what is CFD modeling and how it helps design everything from supercars to skyscrapers, this guide will walk you through the essentials. We will explore the core principles of the CFD modeling process, breaking down complex concepts into understandable steps. This technology allows for the analysis and optimization of designs before a physical prototype is even built, saving significant time and resources.

What is CFD Modeling?

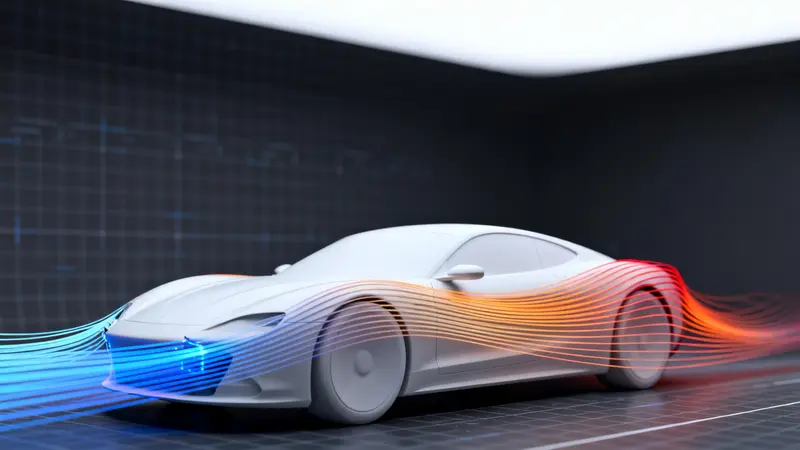

At its heart, CFD is a branch of fluid mechanics that uses numerical analysis and data structures to solve and analyse problems that involve fluid flows. Computers are used to perform the calculations required to simulate the interaction of liquids and gases with surfaces defined by boundary conditions. Think of it as a virtual wind tunnel or water tank. Instead of building a physical model and testing it, engineers can create a digital replica and use sophisticated algorithms to predict how it will behave in the real world. This approach provides not just a result but a deep insight into the mechanics of the system being studied. For those interested in how complex systems are modeled in other fields, understanding what is CFD trading can offer a fascinating parallel in the financial world.

The Fundamentals of Computational Fluid Dynamics

Computational Fluid Dynamics is built on the Navier-Stokes equations—a set of differential equations that describe the motion of viscous fluid substances. Because these equations are incredibly complex and nearly impossible to solve analytically for most real-world scenarios, CFD provides a method to approximate their solutions using numerical methods. The core idea is to break down a large, complex problem into millions of small, simple calculations that a computer can handle efficiently.

- Simulation over Experimentation: It provides a cost-effective and detailed alternative to physical experiments.

- Detailed Insight: It allows you to see and understand phenomena that are invisible to the naked eye, such as turbulence or temperature gradients.

- Predictive Power: It enables engineers to predict performance, identify design flaws, and optimise efficiency before committing to manufacturing.

Core Principles: Meshing, Solvers, and Physics

The entire CFD process rests on three fundamental pillars:

- Meshing (or Gridding): This is the process of dividing the entire physical domain of the problem into thousands or millions of smaller, non-overlapping subdomains called cells or elements. Imagine creating a high-resolution digital mosaic of your object and the fluid around it. The quality of the mesh is crucial for the accuracy of the results—finer meshes in critical areas yield more precise data but require more computational power.

- Solvers: These are the numerical engines that solve the governing mathematical equations for each cell in the mesh. The solver iteratively calculates variables like velocity, pressure, and temperature until the solution converges, meaning the changes between iterations become negligibly small.

- Physics: This involves defining the physical properties of the fluid (e.g., viscosity, density) and the nature of the flow (e.g., turbulence, heat transfer). The chosen physics models dictate which equations the solver will use to simulate the real-world behaviour of the fluid.

Key Takeaway: The accuracy of a CFD simulation is a direct result of the quality of its setup—a well-defined mesh, appropriate physics models, and a robust solver are all essential for reliable results.

How Does the CFD Modeling Process Work?

The CFD workflow is a systematic, multi-stage process that transforms a design concept into detailed performance data. Each step builds upon the last, requiring careful attention to detail to ensure the final simulation is both accurate and meaningful.

Step 1: Pre-Processing and Geometry Setup

This is the foundational stage where the simulation is prepared. It begins with creating or importing a CAD (Computer-Aided Design) model of the object being analysed. This geometry must often be simplified and cleaned to remove unnecessary details that would complicate the meshing process without adding value to the simulation. Once the geometry is ready, the fluid domain is defined, and the meshing process begins. The user sets boundary conditions here, which are critical inputs that tell the software how the fluid behaves at the edges of the domain (e.g., inlet velocity, outlet pressure).

Step 2: Solving the Mathematical Equations

With the pre-processing complete, the solver takes over. This stage is computationally intensive and can take anywhere from minutes to weeks, depending on the complexity of the problem and the available hardware. The solver applies the chosen physics models and iteratively solves the governing equations across the entire mesh. The user monitors the solution’s convergence to ensure that the calculations are stable and progressing towards a steady and accurate result. For those managing complex data, reliable platforms are key. For instance, traders rely on tools like Ultima Markets MT5 for executing complex strategies.

Step 3: Post-Processing and Visualizing Results

Once the solver has finished its calculations, the raw data needs to be interpreted. This is the post-processing stage, where the vast amount of numerical data is translated into insightful visualizations. Engineers use a variety of tools to analyse the results:

- Contour Plots: Colour maps showing the distribution of properties like pressure, velocity, or temperature.

- Vector Plots: Arrows indicating the direction and magnitude of the fluid’s velocity.

- Streamlines: Lines that trace the path of fluid particles, offering a clear view of flow patterns.

- Animations: Dynamic visualizations that show how the flow evolves over time.

This visual feedback allows designers to identify areas of high drag, poor thermal performance, or inefficient flow, which can then be used to refine the design.

Recommended Reading

For those interested in exploring complex analytical tools further, our guide on CFD Trading Tips and Strategies offers insights into how modeling and strategy are applied in the financial markets.

Key Types of CFD Models and Their Uses

Not all fluid flows are the same, and CFD provides a range of models to simulate different physical phenomena accurately. The choice of model depends entirely on the nature of the problem being solved.

Understanding Turbulence Models (k-epsilon vs. k-omega)

Turbulence is a chaotic and complex fluid motion that is present in most engineering applications. Because directly simulating it is computationally impossible for most cases, turbulence models are used to predict its effects. The two most common models are the k-epsilon (k-ε) and k-omega (k-ω) models.

| Model | Strengths | Best For |

|---|---|---|

| k-epsilon (k-ε) | Robust, computationally inexpensive, and good for fully turbulent flows away from walls. | General-purpose simulations, external aerodynamics, and flows where boundary layers are not the primary focus. |

| k-omega (k-ω) | Highly accurate in the boundary layer region (close to surfaces), good for flows with pressure gradients. | Aerospace applications, internal flows, and situations where flow separation and near-wall behaviour are critical. |

Laminar vs. Turbulent Flow Models

The fundamental distinction in fluid dynamics is between laminar and turbulent flow. Laminar flow is smooth and orderly, with fluid particles moving in parallel layers (like honey pouring from a jar). Turbulent flow is chaotic and irregular, with eddies and swirls (like a rapidly flowing river). CFD simulations must correctly identify the flow regime and apply the appropriate models, as the physics governing them are vastly different.

Multiphase and Heat Transfer Models

Many real-world problems involve more than just a single fluid or are affected by temperature. CFD can handle these complexities:

- Multiphase Models: Used for simulating systems with multiple fluids, such as the interaction of water and air for a ship’s hull or oil and gas in a pipeline.

- Heat Transfer Models: Essential for analysing cooling and heating processes. These models simulate conduction, convection, and radiation to predict temperature distributions, which is vital for applications like electronics cooling or engine design.

Real-World Applications of CFD Modeling

CFD is not just an academic tool; it is integral to innovation across numerous industries. Its versatility allows it to solve a wide array of practical problems, leading to better, safer, and more efficient products. Ensuring the security of data and investments in such high-tech fields is paramount, which is why understanding fund safety is crucial for professionals in any data-driven industry.

Aerospace and Automotive Engineering

This is the classic application of CFD. In aerospace, it’s used to design aircraft wings, optimise engine combustion, and predict the aerodynamic forces acting on a vehicle. In the automotive industry, CFD is essential for reducing drag to improve fuel efficiency, managing engine cooling, and ensuring passenger comfort by optimising the in-cabin climate control system.

HVAC and Environmental Design

In architecture and civil engineering, CFD helps design heating, ventilation, and air conditioning (HVAC) systems that provide maximum comfort with minimum energy consumption. It is also used to model the dispersion of pollutants in the atmosphere, assess wind loads on buildings, and plan for smoke extraction in case of a fire.

Electronics Cooling and Thermal Management

Modern electronic devices generate a tremendous amount of heat in a small space. CFD is critical for designing effective cooling solutions, such as heat sinks and fans, to prevent components like CPUs and GPUs from overheating. By simulating airflow and heat transfer, engineers can ensure device reliability and longevity. As technology and markets evolve, staying informed through reliable sources, such as Ultima Markets Reviews, is beneficial for any professional.

Conclusion

CFD modeling has transformed from a niche academic pursuit into an indispensable tool for modern engineering and design. By providing a virtual window into the complex world of fluid dynamics, it allows for unparalleled insight, innovation, and optimisation. From making cars more fuel-efficient to ensuring our electronic devices don’t overheat, the applications of CFD are vast and continue to grow. While mastering it requires expertise, understanding its fundamental principles is the first step towards appreciating its profound impact on the world around us.

Explore Further

Ready to delve deeper into advanced analytical methods? Our article on what is CFD trading explores how similar principles of modeling and analysis are applied in finance.

FAQ

1. What software is commonly used for CFD modeling?

The industry is dominated by a few key players. Commercial software like Ansys Fluent, Siemens STAR-CCM+, and Autodesk CFD are widely used for their comprehensive features and support. There is also a powerful, open-source alternative called OpenFOAM, which is highly popular in academia and among experts who require customisation.

2. How accurate is CFD analysis?

The accuracy of CFD is not absolute; it is a simulation, not a perfect replica of reality. Its accuracy depends heavily on the quality of the inputs: the mesh resolution, the appropriateness of the physics models, and the correctness of the boundary conditions. When done correctly by an experienced user, CFD results can be highly accurate and closely match real-world experimental data.

3. What is the difference between CFD and FEA?

CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) are both simulation methods, but they analyse different physics. CFD is used for problems involving fluid flow, heat transfer, and chemical reactions. In contrast, FEA is used for structural analysis to understand how solid objects respond to stress, vibration, and heat. Essentially, CFD deals with fluids, while FEA deals with solids.

4. Is CFD difficult to learn?

CFD has a steep learning curve. It requires a solid understanding of fluid mechanics, thermodynamics, and numerical methods. However, modern CFD software has become much more user-friendly, with graphical interfaces and automated workflows that make it more accessible. While anyone can learn to operate the software, becoming a proficient CFD analyst who can produce reliable and meaningful results requires significant education and experience.

*The content of this article represents the author’s personal views only and is for reference purposes. It does not constitute any professional advice.